close

Choose Your Site

Global

Social Media

SJ55/120, SJ65/132

Eans Machine

847720900

| Availability: | |

|---|---|

PVC Corner Beads Trims Guard Production Process:

1. Heating and cooling mixing syetm: mix PVC resin, calcium carbonate with addtives according to the formula

2. Materails charging - extrusion - die - vacuum cooling - hauling off - online holes punching - cutting - auto stacking, Get the finished PVC corners

3. Waste PVC recyling (crush the waste PVC conrers, and mill it into powder for next extrusion)

Features of PVC Corner Beads/Angle Bead Production Line:

- Our techinical is fetched in Europe and America advanced technology and uniting with the domestic condition, our company develops this production line.

- The extrusion system is well designed, and it is easy and convenient for operation and maintain

- Economical price, suitable for large-scale investment. We can provide the solution list at your factory scale.

- This production line is used to manufacture different section shape and height of pvc profiles, such as, pvc corner beads, pvc cable trunking, pvc edge bands, pvc profiles, etc.

PVC corner beads has the advantages of high strength, good adhesion, and full combination with putty. It is easy to construct, reduces labor intensity, speeds up construction progress, and reduces project costs. It is straight and beautiful, and greatly enhances the impact resistance of the corner, protecting the corner from damage, and effectively avoiding the trouble of repeated repairs due to damage to the corner.

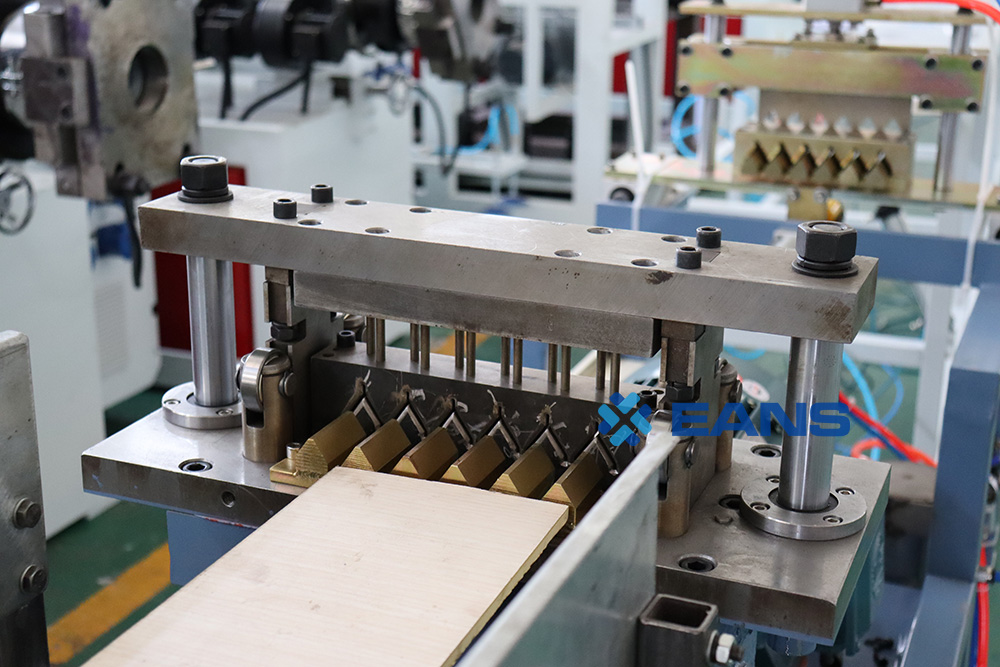

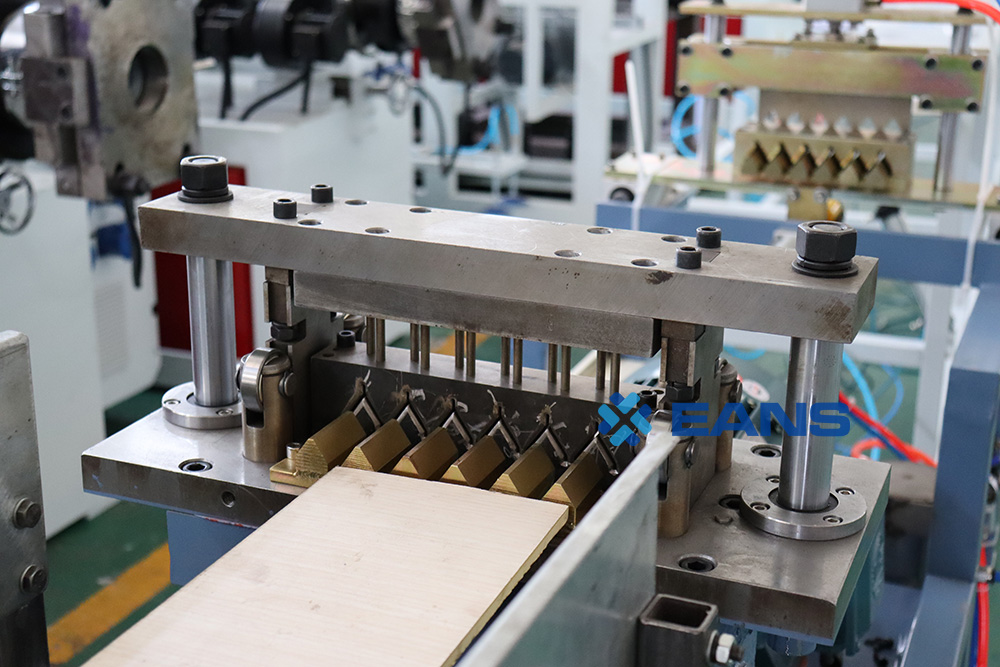

PVC corner beads extrusion die and calibration mold:

PVC Corner Beads / Angle Beads Extrusion Machine List

1. Automatic raw materials charger - 1 set

2. Conical twin screw extruder - 1 set

3. Extrusion die and calibration mould - 1 set

4. Vacuum cooling table - 1 set

5. Hauling off - 1 set

6. Auto cutting machine - 1 set

7. Online hole punching machine

8. Finished PVC corner beads auto stacker - 1 set

Parameters of PVC corner beads making machine

| Model | Capacity | Mold Cavity | Main motor | Speed |

| SJ55/110 | 150 kg/hour | 4 or 6 | 22 KW | 15-20 m/min |

| SJ65/132 | 250 kg/hour | 6 | 37 KW | 20-30 m/min |

PVC Corner Beads Trims Guard Production Process:

1. Heating and cooling mixing syetm: mix PVC resin, calcium carbonate with addtives according to the formula

2. Materails charging - extrusion - die - vacuum cooling - hauling off - online holes punching - cutting - auto stacking, Get the finished PVC corners

3. Waste PVC recyling (crush the waste PVC conrers, and mill it into powder for next extrusion)

Features of PVC Corner Beads/Angle Bead Production Line:

- Our techinical is fetched in Europe and America advanced technology and uniting with the domestic condition, our company develops this production line.

- The extrusion system is well designed, and it is easy and convenient for operation and maintain

- Economical price, suitable for large-scale investment. We can provide the solution list at your factory scale.

- This production line is used to manufacture different section shape and height of pvc profiles, such as, pvc corner beads, pvc cable trunking, pvc edge bands, pvc profiles, etc.

PVC corner beads has the advantages of high strength, good adhesion, and full combination with putty. It is easy to construct, reduces labor intensity, speeds up construction progress, and reduces project costs. It is straight and beautiful, and greatly enhances the impact resistance of the corner, protecting the corner from damage, and effectively avoiding the trouble of repeated repairs due to damage to the corner.

PVC corner beads extrusion die and calibration mold:

PVC Corner Beads / Angle Beads Extrusion Machine List

1. Automatic raw materials charger - 1 set

2. Conical twin screw extruder - 1 set

3. Extrusion die and calibration mould - 1 set

4. Vacuum cooling table - 1 set

5. Hauling off - 1 set

6. Auto cutting machine - 1 set

7. Online hole punching machine

8. Finished PVC corner beads auto stacker - 1 set

Parameters of PVC corner beads making machine

| Model | Capacity | Mold Cavity | Main motor | Speed |

| SJ55/110 | 150 kg/hour | 4 or 6 | 22 KW | 15-20 m/min |

| SJ65/132 | 250 kg/hour | 6 | 37 KW | 20-30 m/min |